Rogue OCTANE SSK (SELECT YOUR MODEL)

To appreciate the specific advantages of the OCTANE short shifter lever, one must understand the details that make it unique to all others.

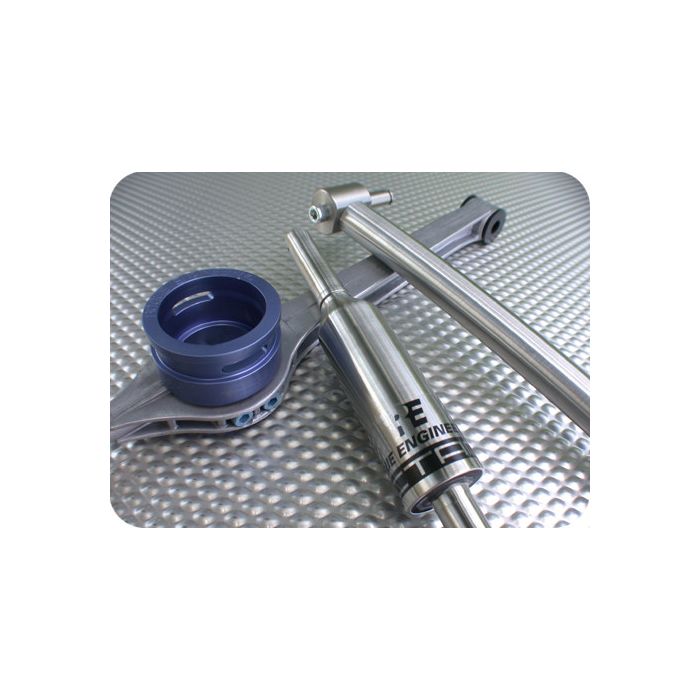

Shifter Lever Upper

OCTANE short shift kits now feature a CNC-machined 303 stainless steel upper. This change adds approximately 100g more to the top of the shifter lever, helping to improve shifter feel. This small increase in mass above is compliments the incorporated WSR (not all models). The outside profile has been designed to precisely reproduce the dimensions the factory shifter lever. This means that the use of factory illuminated shift knobs is possible.

Bonding Technology

Until now, only the factory shifter lever was designed to be a vibration-absorbing, acoustically damped unit. BMW engineers employ vibration-dampening materials in their cars motor mounts, transmission mounts, subframe mounts and in various other areas for good reason ± to isolate the cabin from excess vibration and noise. The OCTANE short shifter lever uses superior materials, bonded in a similar manner in order to achieve a shorter, more positive shift throw without sacrificing the vibration dampening that BMW engineers built in. Some companies may allude that their "manufactured" lever is in some way superior to a factory lever. Unfortunately, their "bolted" technology is nothing more than a machined version of the shifter that BMW was putting in its cars back in 1972. Why take a step backwards? If you want to maintain the vibration absorbing characteristics of a factory shifter, then your shifter lever better be made in a similar manner, using comparable materials!

Shifter Lever Lower

The lower portion of the OCTANE short shifter is made from CNC'd 303 stainless steel. This material was selected because of its superior corrosion resistance and strength.

Pivot Ball and Pivot Bushing

After extensive research and testing, we have discovered and implemented the ideal pivot material. The thermoplastic material used in the OCTANE short shifter maintains the vibration-dampening qualities and built-in lubricity of the stock shifters thermoplastic pivot, but adds superior resistance to heat and wear. Unlike rigid metal balls or bushings, Ertalyte TX is proving to be the best material for the application. With a coefficient of friction that is 421% better than a stainless steel pivot ball, it combines all the benefits of smooth movement with durability beyond all other thermoplastics. Even with all of the fantastic properties of Ertalyte TX, we have designed the lower pivot point to be replaceable, should it ever need to be replaced in the future for any reason.